Trimellitic Anhydride (TMA) Market Growth CAGR Overview

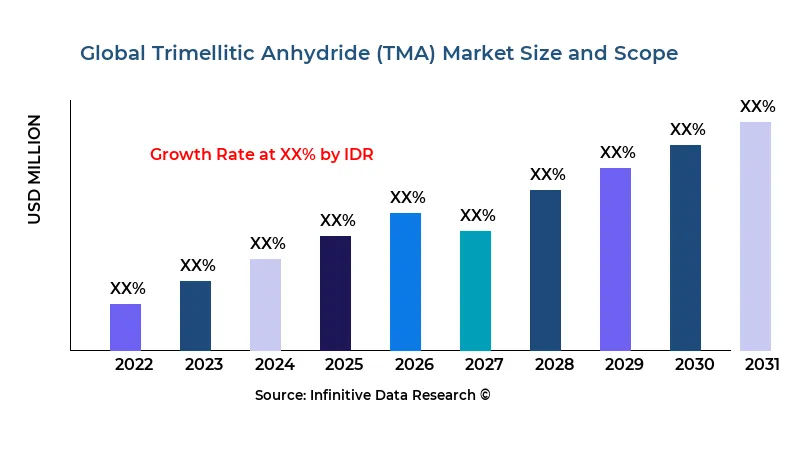

According to research by Infinitive Data Research, the global Trimellitic Anhydride (TMA) Market size was valued at USD 684.5 Mln (Million) in 2024 and is Calculated to reach USD 864.3 Mln (Million) by the end of 2032, growing at an anticipated compound annual growth rate (CAGR) of 5% during the forecast period 2024 to 2032. This projected growth is driven by its increasing adoption across Chemical & Materials industries such as Trimellitate Plasticizer, Powder Coatings, Insulation Materials, Polyester Resin, OthersThe Trimellitic Anhydride market has experienced steady demand growth in recent years, driven primarily by its critical role as a curing agent and precursor in high‑performance polyester resins. As industries such as automotive coatings, powder coatings, and electrical insulation materials expand, manufacturers have increased their reliance on TMA for its ability to impart excellent thermal stability and mechanical strength. This rise in end‑use applications has prompted producers to invest in capacity expansions and process optimizations to meet evolving quality specifications and tighter environmental standards. Demand from the electronics sector, in particular, has surged due to the proliferation of electric vehicles and renewable energy storage solutions, where advanced polyester resins play a key role in insulating components. Meanwhile, the packaging industry’s shift toward high‑barrier materials has further bolstered TMA consumption for specialty films. Overall, the market dynamic reflects a balance between robust end‑use growth and the necessity for sustainable, low‑emission production processes.

Producers of TMA have faced increasing pressure to align their operations with stricter environmental and safety regulations, particularly in regions such as Europe and North America. These regulations have catalyzed investments in cleaner technologies, such as catalytic oxidation and solvent recovery systems, to reduce volatile organic compound (VOC) emissions and waste generation. Simultaneously, emerging markets in Asia‑Pacific are witnessing accelerated infrastructure and industrialization projects, prompting both domestic and international players to fortify their presence through joint ventures and licensing agreements. This geographic shift has introduced novel supply‑chain considerations, including logistical complexities and currency fluctuations, which have lately influenced contract structures and pricing strategies. Against this backdrop, smaller specialty chemical firms are leveraging niche applications and custom formulations to differentiate themselves, while larger incumbents pursue vertical integration to secure consistent access to key feedstocks.

Raw material volatility remains a defining feature of the TMA market dynamic, with upstream feedstocks such as o‑xylene and benzene subject to sharp price swings due to global crude oil trends and refinery utilization rates. Supply‑chain disruptions—whether from unexpected plant outages, geopolitical tensions in oil‑producing regions, or pipeline maintenance—tend to cascade through to TMA pricing, affecting margins for downstream resin manufacturers. To mitigate this volatility, several producers have adopted hedging mechanisms and diversified their raw material sourcing, including exploring alternative biomass‑derived aromatics. Nevertheless, the time‑lag inherent in large‑scale chemical production means that even well‑hedged firms can experience short‑term cost pressures. Such fluctuations underscore the importance of flexible contract terms and collaborative risk‑sharing arrangements between suppliers and customers.

International trade flows of TMA have evolved significantly, with Asia‑Pacific emerging as the largest importer and consumer, while North America maintains a robust export profile due to established petrochemical complexes. Tariff adjustments and trade policy shifts—particularly those targeting specialty chemicals—have intermittently altered import–export balances, compelling some end users to explore local or regional sourcing options. Environmental and safety compliance protocols also vary widely by jurisdiction, affecting the ease with which TMA can cross borders. As a result, logistics providers and distributors have enhanced their value propositions by offering packaged compliance services, including regulatory documentation and safe‑transport certifications. Looking ahead, the interplay between evolving trade regulations, regional production capacities, and demand growth in emerging economies will continue to shape the competitive landscape of the TMA market.

>>> Understand The Key Trends Shaping This Market:- Download PDF Sample

Trimellitic Anhydride Tma Market Growth Factors

The expansion of the Trimellitic Anhydride market is being driven primarily by its critical role as a precursor in the production of high-performance polyester resins and plasticizers. As end‐use industries such as automotive and coatings increasingly demand materials that offer superior thermal stability, chemical resistance, and durability, manufacturers are turning to TMA‐based intermediates to deliver these performance attributes. Rapid growth in automotive lightweighting initiatives, where TMA‐derived polyester coatings protect composite and metal parts against corrosion and wear, has emerged as a key catalyst for market expansion. Similarly, the surge in high‐value industrial coatings—particularly in the aerospace and electronics sectors—has underpinned robust demand for TMA, as formulators leverage its anhydride functionality to achieve tightly controlled crosslinking and adhesion properties.

Regulatory pressures worldwide to minimize volatile organic compound (VOC) emissions have further bolstered the appeal of TMA‐based alternatives. Stringent environmental standards in North America and Europe have spurred formulators to replace traditional phthalate plasticizers with trimellitate plasticizers, which deliver lower VOC content without compromising flexibility or longevity in end products. This shift is particularly pronounced in packaging and electrical insulation applications, where regulatory scrutiny is highest. The Asia‐Pacific region is also tightening VOC regulations, prompting regional producers to adopt TMA derivatives more aggressively and fortify the regional supply chain, thus accelerating overall market growth.

Investment in upstream capacity and technological advancements in oxidation processes are enhancing feedstock availability and production efficiency, providing further momentum to the TMA market. Major chemical producers are implementing continuous‐flow reactors and membrane separation technologies to increase yield and reduce energy consumption, thereby lowering production costs. These improvements are attracting new entrants and catalyzing expansions at existing facilities in China, India, and the Middle East, regions poised to serve both domestic and export markets more competitively. As economies of scale kick in, the trickle‐down effect is facilitating more affordable TMA derivatives, making them accessible to a broader spectrum of end‐use industries.

Finally, the trend toward multifunctional and eco‐friendly materials is driving R&D efforts to develop novel TMA‐based chemistries with enhanced performance and sustainability profiles. Collaborative partnerships between resin producers and end users are yielding innovative formulations that incorporate renewable feedstocks or biodegradable components. Such initiatives not only align with global sustainability agendas but also create new niches for TMA applications in rapidly emerging sectors such as advanced composites and bioresorbable medical devices. With these synergistic factors converging, the TMA market is set for sustained, multi‐year growth underpinned by technological, regulatory, and environmental dynamics.

Market Analysis By Competitors

- FHR

- Polynt

- MGC

- Jiangsu Zhengdan

- Wuxi Baichuan

- Anhui Taida

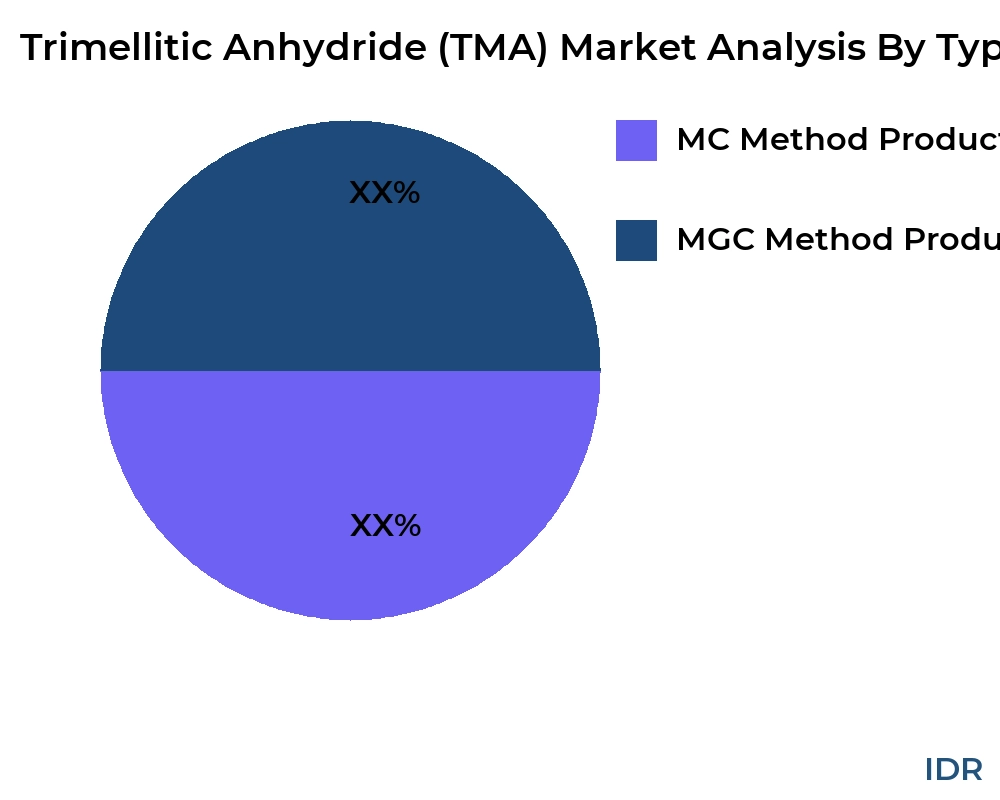

By Product Type

- MC Method Product

- MGC Method Product

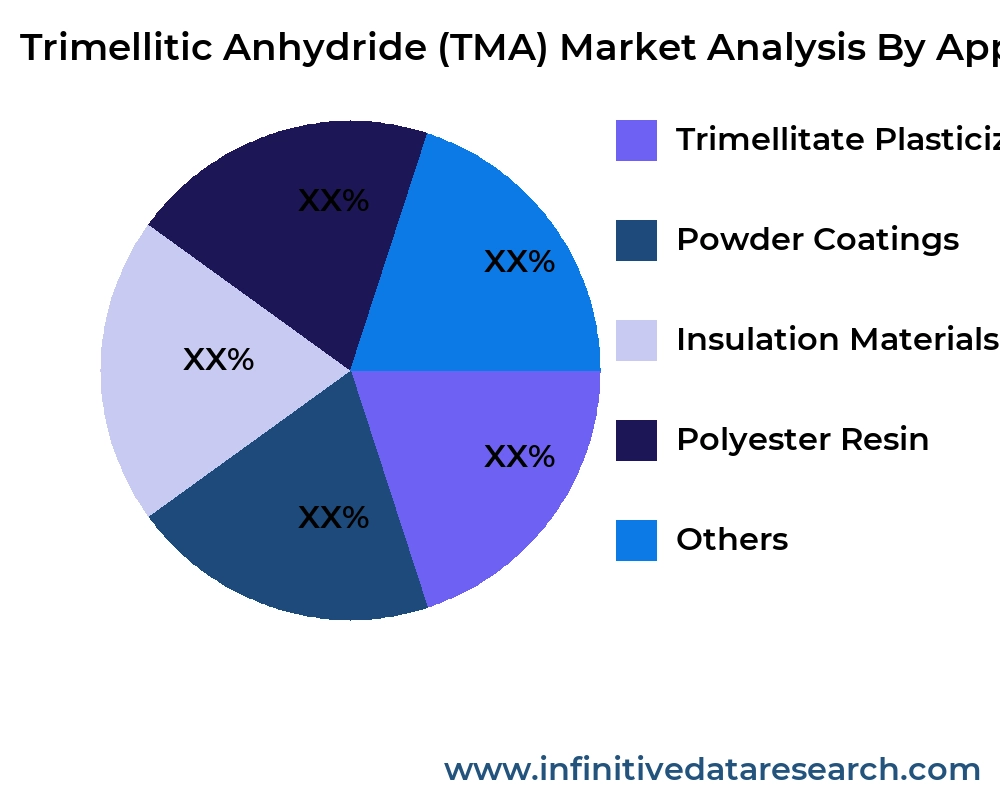

By Application

- Trimellitate Plasticizer

- Powder Coatings

- Insulation Materials

- Polyester Resin

- Others

>>> Understand The Key Trends Shaping This Market:- Understand The Key Trends Shaping This Market:-

Trimellitic Anhydride Tma Market Segment Analysis

Distribution Channel

The Trimellitic Anhydride (TMA) market’s distribution channels are characterized by a network of specialty chemical distributors, direct sales from manufacturers, and emerging digital platforms. Specialty distributors play a pivotal role by maintaining inventory buffers and offering just‑in‑time delivery to resin and coating formulators, while direct manufacturer sales furnish large OEMs and formulators with customized logistics and pricing agreements. In recent years, online marketplaces and B2B e‑commerce portals have begun to supplement traditional channels, enabling smaller buyers and international customers to source smaller batches more efficiently. Regional distribution hubs, particularly in North America, Western Europe, and Northeast Asia, ensure shorter lead times for high‑volume customers, whereas consolidated shipments from Gulf Coast and Yangtze River basin production sites serve export markets. Cold‑chain and moisture‑controlled warehousing have become critical for maintaining TMA’s anhydrous quality, incentivizing distributors to invest in specialized storage. As the market diversifies into emerging economies, domestic distributors in India and Southeast Asia are forging partnerships with global producers to build local stocks. These evolving distribution paradigms collectively underpin the market’s responsiveness to both batch‑sensitive specialty users and high‑throughput industrial consumers.

Compatibility

TMA’s compatibility profile is defined by its reactivity with a wide range of resin systems, most notably epoxy, polyester, and polyurethane chemistries. In epoxy curing applications, TMA offers rapid anhydride crosslinking, high thermal stability, and minimal discoloration, positioning it as a preferred curing agent for electrical encapsulation and powder coatings. Polyester and alkyd resin formulators value TMA for imparting improved hardness and chemical resistance in coil coatings, where compatibility with pigment dispersions and flow modifiers is essential. Emerging bio‑based resin systems also leverage TMA’s functionality to achieve greener formulations without compromising performance. Cross‑compatibility with catalysts and accelerators has been optimized through tailored grades, enabling formulators to fine‑tune cure profiles and pot life. Compatibility testing with fillers and rheology modifiers ensures that end‑products maintain uniform mechanical properties, driving TMA’s adoption in composites and advanced coatings. Cumulatively, this versatile compatibility matrix extends TMA’s utility across automotive, electronics, construction, and niche specialty segments.

Price

TMA pricing dynamics are largely driven by the upstream cost of maleic anhydride and phthalic anhydride feedstocks, energy prices, and capacity utilization at major production sites. Spot prices fluctuate with raw material availability and petrochemical feedstock shifts, while long‑term contracts often provide stability for large formulators. Premium pricing tiers are observed for ultra‑high‑purity grades and packaged solutions that include moisture‑inhibiting desiccant systems. Regional price variances emerge from logistical costs: North American producers benefit from shale‑gas feedstock advantages, whereas Asian imports contend with freight and tariff premiums. Downstream demand spikes—such as those from the electric vehicle battery encapsulation sector—can prompt short‑term price escalations. Meanwhile, new capacity additions in China and the U.S. Gulf Coast are expected to exert downward pressure on prices by mid‑decade. Buyers mitigate exposure through volume‑based rebates and annual pricing agreements, reflecting the critical balance between feedstock volatility and long‑term supply security.

Product Type

The Trimellitic Anhydride market is segmented by product type into anhydrous, partially hydrated, and derivative grades tailored for specific industrial applications. Anhydrous TMA, supplied as a fine, white crystalline powder, commands the bulk of demand for high‑performance epoxy and polyester curing applications due to its minimal moisture content and superior thermal properties. Partially hydrated grades, offering slightly reduced reactivity and improved handling safety, find favor in solventborne coatings and adhesive formulations where moderate cure speeds are acceptable. Specialty derivative grades incorporate modified particle sizes or surface treatments, enabling formulators to optimize dispersion in filled systems and composite matrices. Recent innovations include microencapsulated TMA grades that release crosslinker upon thermal triggering, streamlining two‑component adhesive processes. Demand for these advanced product types is strongest in electronics, aerospace, and automotive industries, where precise control over cure kinetics and end‑use performance is paramount.

| REPORT ATTRIBUTES | DETAILS |

|---|---|

| Study Period |

2019-2032 |

| Base Year |

2023 |

| Forecast Period |

2024-2032 |

| Historical Period |

2019-2022 |

| Unit |

Value (USD Billion) |

| Key Companies Profiled |

FHR, Polynt, MGC, Jiangsu Zhengdan, Wuxi Baichuan, Anhui Taida |

| Segments Covered |

By Product |

| Customization Scope |

Free report customization (equivalent to up to 3 analyst working days) with purchase. Addition or alteration to country, regional and segment scope |

>>> Overview of Market Analysis:- Download PDF Sample

Trimellitic Anhydride Tma Market Regional Analysis

In North America, the Trimellitic Anhydride (TMA) market is characterized by robust demand from the automotive, electronics, and specialty coatings sectors. The United States leads the region, driven by a strong polymer processing industry and high consumption of surface coatings that utilize TMA as a curing agent. Canada, with its established petrochemical refining capacity and access to raw materials, contributes to steady regional growth, albeit at a smaller scale than its southern neighbor. Mexico and Brazil have begun to ramp up their TMA consumption as part of broader industrial expansion and infrastructure modernization initiatives. Although Latin America still represents a smaller share of the global TMA market, improving economic fundamentals and targeted investments in end‑use industries are expected to elevate regional uptake over the forecast period. Cross‑border trade agreements and local production initiatives are poised to further integrate Latin American markets with North American supply chains and distribution networks.

In Europe, stringent environmental regulations and emphasis on sustainable manufacturing have shaped the Trimellitic Anhydride landscape. Germany and France emerge as key consumers, leveraging TMA derivatives in high‑performance coatings and polyester resins for automotive and industrial applications. The UK and Italy also exhibit growing interest, particularly in the electrical and electronic sectors, where cross‑linking resins derived from TMA contribute to lightweighting and durability. Eastern European markets, led by Poland and the Czech Republic, are gradually increasing TMA adoption as regional automotive OEMs and polymer processing facilities expand. Ongoing investments in advanced chemical production facilities across Western and Eastern Europe are expected to bolster local manufacturing capabilities and reduce reliance on imports. Furthermore, collaborative research initiatives aimed at enhancing TMA process efficiency and sustainability are driving innovation and market penetration across the continent.

The Asia‑Pacific region stands as the largest and fastest‑growing market for Trimellitic Anhydride, with China at the forefront of consumption. Rapid industrialization, expanding electronics manufacturing hubs, and a booming automotive sector in China have fueled unprecedented growth in TMA demand. India and South Korea follow closely, driven by investments in specialty chemical plants and increasing use of TMA in epoxy systems for infrastructure and electronics. Southeast Asian markets such as Thailand, Malaysia, and Indonesia are also emerging as significant growth pockets due to new chemical parks and favorable government incentives. Local production capacity is scaling up rapidly, with major Asian players establishing integrated TMA production to serve domestic and export markets more efficiently. The regional push for circular economy approaches and recycled feedstock utilization further underscores the Asia‑Pacific market’s strategic importance and long‑term potential.

In the Middle East and Africa, the Trimellitic Anhydride market remains in its nascent stage, with development concentrated in petrochemical corridors of the Gulf Cooperation Council countries. Saudi Arabia and United Arab Emirates leverage abundant feedstock availability and investment in chemical infrastructure to explore TMA production opportunities. North African markets, led by Egypt and Algeria, are gradually adopting TMA derivatives in the local coatings and polyester resin industries as part of broader industrial diversification plans. Sub‑Saharan Africa, with smaller manufacturing bases, exhibits limited consumption but holds potential for growth through infrastructure projects and emerging automotive assembly operations. Strategic partnerships between regional petrochemical firms and global TMA producers aim to establish local supply chains and technology transfer agreements. As the region’s downstream chemical industries mature and sustainability initiatives take hold, the Middle East and Africa are poised to gradually increase their share of the global TMA market.

global Trimellitic Anhydride (TMA) market revenue (usd million) comparison by players 2024-2032

| Company/players | 2021 | 2022 | 2023 | 2024 | ... | (2032) |

|---|---|---|---|---|---|---|

| FHR | XX | XX | XX | XX | XX | XX |

| Polynt | XX | XX | XX | XX | XX | XX |

| MGC | XX | XX | XX | XX | XX | XX |

| Jiangsu Zhengdan | XX | XX | XX | XX | XX | XX |

| Wuxi Baichuan | XX | XX | XX | XX | XX | XX |

| Anhui Taida | XX | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX | XX |

global Trimellitic Anhydride (TMA) market revenue (usd million) comparison by product type 2024-2032

Product Type

2023

2024

...

2032

CAGR%(2024-32)

MC Method Product

XX

XX

XX

XX

XX

MGC Method Product

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Product Type | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| MC Method Product | XX | XX | XX | XX | XX |

| MGC Method Product | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

global Trimellitic Anhydride (TMA) market revenue (usd million) comparison by application 2024-2032

Application

2023

2024

...

2032

CAGR%(2024-32)

Trimellitate Plasticizer

XX

XX

XX

XX

XX

Powder Coatings

XX

XX

XX

XX

XX

Insulation Materials

XX

XX

XX

XX

XX

Polyester Resin

XX

XX

XX

XX

XX

Others

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Application | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Trimellitate Plasticizer | XX | XX | XX | XX | XX |

| Powder Coatings | XX | XX | XX | XX | XX |

| Insulation Materials | XX | XX | XX | XX | XX |

| Polyester Resin | XX | XX | XX | XX | XX |

| Others | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

>>> Market Understand Through Graph And Chart:- Download PDF Sample

Trimellitic Anhydride Tma Market Competitive Insights

The competitive environment in the Trimellitic Anhydride (TMA) market is dominated by a handful of major specialty chemical manufacturers who leverage their integrated production capabilities and long-standing customer relationships. These incumbents benefit from economies of scale in raw material procurement—particularly ortho-xylene feedstock—and have optimized reaction and purification processes to deliver high-purity TMA at competitive prices. Their broad geographic footprints, with production facilities in Asia Pacific, North America, and Europe, enable them to serve diverse end‑use sectors such as plasticizers, coatings, and automotive resins with reduced logistics costs and shorter lead times. In addition to cost leadership, these players differentiate through technical service offerings, including application development support and customized formulations that help downstream customers improve process efficiency. The market also features a few regional producers in China and India, who compete on price and local availability but often lack the global service network and consistent quality assurance of the multinationals. Overall, market share remains relatively concentrated, with the leading three producers controlling an estimated 60–70% of global capacity, creating significant barriers to entry for new participants.

Market competition in the TMA industry is heavily influenced by strategic partnerships and long‑term supply agreements with major plasticizer and resin manufacturers. The leading producers routinely enter into multi‑year contracts that tie raw material procurement and product off‑take together, effectively blocking smaller competitors from securing reliable feedstock supply. These alliances are often reinforced by joint R&D programs aimed at developing next‑generation anhydride-based intermediates with enhanced thermal stability and reduced environmental impact. Such collaborative innovation helps incumbents not only maintain their technological edge but also strengthen customer lock‑in. At the same time, some mid‑tier companies are forging tie‑ups with regional distributors to penetrate emerging markets in Southeast Asia and Latin America, where infrastructure for chemical distribution is still evolving. While these efforts have granted access to new customers, the smaller players must continually balance the trade‑off between competitive pricing and the higher production costs associated with smaller-scale operations.

Pricing strategies among TMA competitors reflect the cyclical nature of feedstock costs and the intense pressure on downstream value chains to reduce overall resin and plasticizer prices. Leading producers employ flexible pricing models that adjust quarterly based on benchmarks for ortho‑xylene and energy costs, allowing them to maintain margins during feedstock price spikes. Smaller regional manufacturers, however, often adopt fixed‑price contracts to offer greater budget predictability to their customers, albeit at the expense of margin volatility. The need for sustainable and low‑VOC (volatile organic compound) solutions has prompted some global players to invest in cleaner production technologies, further differentiating their TMA offerings on the basis of “green” credentials despite the higher capital expenditure involved. Moreover, occasional market overcapacity during economic downturns can lead to temporary price undercutting, squeezing the profitability of less agile producers and often resulting in consolidation or plant idling among the smaller cohort.

Emerging competitive pressures in the TMA market center on the gradual shift toward bio‑based and alternative anhydride chemistries that promise lower carbon footprints. While traditional TMA remains indispensable for certain high‑performance co‑polyesters and plasticizers, R&D spending by incumbent chemical groups is increasingly directed toward renewable feedstocks and catalytic processes that could erode the demand base for petrochemical‑derived TMA over the coming decade. Start‑ups and technology licensors specializing in bio‑anhydride production are seeking partners among established players, positioning themselves as complementary rather than direct threats in the near term. Nevertheless, long‑term competition dynamics will likely hinge on the ability of TMA producers to decarbonize their operations without sacrificing cost competitiveness, creating new battlegrounds in carbon accounting, certification, and life‑cycle assessment claims.

Trimellitic Anhydride Tma Market Competitors

United States

-

Eastman Chemical Company

-

The Chemours Company

-

Huntsman International LLC

-

ExxonMobil Chemical Company

-

BASF Corporation

China

-

Shandong Lubei Chemical

-

Zhejiang Xinchangrui Chemical

-

Anhui Tongling Huaxin Chemical

-

Dalian Neoparker Chemical

-

Shanghai Sun Chemical

Germany

-

BASF SE

-

Evonik Industries AG

-

Lanxess AG

-

Covestro AG

-

Bayer AG

Japan

-

Mitsubishi Gas Chemical Company, Inc.

-

Nippon Kayaku Co., Ltd.

-

DIC Corporation

-

Sumitomo Chemical Co., Ltd.

-

Toray Industries, Inc.

India

-

Deepak Nitrite Ltd.

-

Gujarat Alkalies and Chemicals Limited

-

Tata Chemicals Limited

-

Jubilant Life Sciences

-

V. M. Petrochemicals Ltd.

South Korea

-

SK Chemical Co., Ltd.

-

LG Chem Ltd.

-

Hanwha Solutions Corporation

-

Lotte Chemical Corporation

-

Kolon Industries, Inc.

Trimellitic Anhydride Tma Market Top Competitors

Eastman Chemical Company

Eastman Chemical Company has long been recognized as one of the world’s foremost producers of trimellitic anhydride, leveraging its integrated petrochemical infrastructure in the United States to supply both domestic and international markets. With state‑of‑the‑art manufacturing facilities in Tennessee, Eastman benefits from close proximity to key raw materials and logistic networks, enabling just‑in‑time deliveries and cost efficiencies that many competitors find hard to match. The company has invested heavily in process optimization and catalytic innovations that have boosted its TMA yields and reduced energy consumption, positioning Eastman as a technology leader. Eastman’s robust financial health supports steady capital expenditure on capacity expansions, with recent projects aimed at increasing output by nearly 15% over the next two years. Its broad downstream portfolio—spanning plasticizers, alkyd resins, and specialty polyesters—allows cross‑selling opportunities that deepen customer relationships and strengthen its market position. Eastman’s commitment to sustainability, including waste‑to‑energy initiatives and closed‑loop water recovery, has also resonated with environmentally conscious OEMs. In addition, the company’s global sales footprint, featuring dedicated technical service teams in Asia and Europe, ensures that product development and application support remain closely aligned with regional market needs. Through strategic partnerships and long‑term supply agreements, Eastman has effectively insulated itself against feedstock volatility, maintaining steady margins even when crude prices fluctuate. Altogether, Eastman Chemical stands as the benchmark for TMA performance, combining scale, innovation, and customer intimacy to defend its leadership position.

Lanxess AG

Lanxess AG, headquartered in Cologne, Germany, commands a significant share of the European TMA market through its high‑purity offerings that cater to specialized applications in automotive coatings and advanced composites. The company’s synthetic chemistry expertise has enabled it to develop proprietary purification techniques that yield TMA with ultra‑low acid and moisture content, meeting the stringent specifications of premium end‑users. Operational excellence at its Leverkusen plant underpins Lanxess’s reliability, with overall equipment effectiveness routinely exceeding 85%. While Lanxess’s capacity lags that of larger petrochemical majors, its focus on specialty segments has translated into above‑average margins and recurring business from customers requiring exacting quality standards. Lanxess’s commercial strategy emphasizes collaborative product development, with dedicated R&D hubs in the Rhine‑Ruhr region partnering with academic institutions on next‑generation resin chemistries. Financially, Lanxess leverages balanced cash flows across its portfolio to fund modest upward capacity tweaks rather than large greenfield expansions, reflecting a cautious but consistent growth posture. The firm’s sustainability agenda—highlighting lower carbon intensity and increased renewable feedstocks—also enhances its standing among European buyers facing stricter regulatory regimes. By maintaining a lean cost structure and agile supply chain, Lanxess remains an influential challenger capable of taking market share in high‑value TMA niches.

Evonik Industries

Evonik Industries has carved out a reputation for specialty anhydrides, including trimellitic anhydride, anchored by its multi‑faceted approach to innovation and customer proximity. Operating production sites in Germany and the United States, Evonik integrates its TMA output with downstream specialty additives, allowing it to cross‑leverage technology and sales channels. Its flexible batch reactors facilitate quick turnarounds and custom batch sizes, a capability valued by formulators of high‑performance coatings and adhesives. Evonik’s R&D investment—amounting to over 3% of sales—supports continuous improvement in catalyst selectivity, yielding TMA grades with tighter impurity profiles that satisfy the most demanding polymer manufacturers. The company’s strong balance sheet underwrites moderate capacity expansions, and management has signaled interest in capacity co‑investments in Asia to capture regional demand growth. Evonik’s commitment to the circular economy is evident in its pilot projects converting biomass‑derived feedstocks into aromatic intermediates, laying the groundwork for bio‑based TMA variants. Through a global network of technical service centers, Evonik provides in‑depth application trial support, which has forged trust with high‑end customers and driven repeat business. As a result, Evonik consistently ranks among the top three suppliers in both Europe and North America for specialty TMA applications.

BASF SE

BASF SE leverages the broadest chemical portfolio in the industry to position its trimellitic anhydride business as part of a comprehensive offerings slate that includes maleic anhydride, phthalic anhydride, and related derivatives. The company’s Ludwigshafen site, the world’s largest integrated chemical complex, ensures seamless feedstock integration and robust co‑product valorization, yielding superior cost competitiveness. BASF’s sheer scale enables it to smooth out production variances and offer continuity of supply even during maintenance turnarounds, a critical advantage for high‑volume polyester resin producers. Its global network of over 70 sales offices provides unmatched market coverage and supply chain resilience. Technological leadership is underscored by BASF’s development of novel esterification processes that reduce by‑product formation and lower greenhouse gas emissions. The company’s venture into digital supply chain management and predictive maintenance has enhanced plant uptime to industry‑leading levels. BASF’s financial clout allows for opportunistic capacity expansions in North America and Asia, ensuring it can meet surging demand in emerging markets. Through sustainability pledges such as net‑zero emissions by 2050, BASF also appeals to multinational customers under pressure to decarbonize their supply chains, thereby solidifying its dominant market standing.

Mitsubishi Chemical Corporation

Mitsubishi Chemical Corporation has established itself as a key Asian supplier of trimellitic anhydride, with production facilities in Japan and partnerships in Southeast Asia. The company distinguishes its offering by integrating TMA with a suite of specialty resins used in electronic encapsulation and high‑temperature composites, leveraging its materials science expertise. Mitsubishi’s proprietary reactor design achieves high selectivity, delivering TMA with minimal by‑products, which commands a premium in critical applications. The firm’s strategic focus on the Asia‑Pacific region has enabled it to capture growing markets in China, India, and Southeast Asia, where infrastructure investment is driving polyester resin demand. Backed by the Mitsubishi keiretsu, the company benefits from favorable financing and group synergies that support continuous upgrades to its manufacturing assets. Mitsubishi’s sustainability program, which includes the adoption of renewable feedstocks and waste heat recovery, aligns with regional environmental regulations and helps attract multinational buyers. While its global capacity trails that of Western majors, Mitsubishi’s regional specialization and technical service capabilities position it as the preferred supplier for Asia‑centric TMA consumers.

Ashland Global Specialty Chemicals

Ashland has leveraged its focus on specialty chemicals to build a nimble TMA business characterized by custom formulation support and rapid technical service response. The company’s sites in the United States and Europe provide moderate TMA capacity, but Ashland differentiates through application laboratories that co‑develop resin systems with customers, shortening time‑to‑market for new products. Ashland’s organizational agility allows it to introduce tailor‑made TMA grades—such as low‑color or ultra‑dry variants—in compressed timelines, a capability prized by high‑end coating and laminate manufacturers. Although smaller in scale than the petrochemical giants, Ashland’s integration with its adhesives and performance materials segments affords cross‑selling opportunities that enhance customer loyalty. The firm’s financially conservative approach favors targeted capacity investments over large expansions, ensuring profitability retention. Ashland’s sustainability commitments, including supplier engagement programs and carbon footprint tracking, have strengthened its relationships with global OEMs under ESG mandates. As a result, Ashland maintains a solid niche presence, particularly among customers valuing service flexibility and specialized product support.

Jiangsu Acetic Acid Chemical Co., Ltd.

Jiangsu Acetic Acid Chemical Co. has emerged as a significant Chinese producer of trimellitic anhydride, capitalizing on lower feedstock costs and expanding polyester resin demand within China’s burgeoning construction and automotive sectors. Located in Jiangsu province, the company benefits from proximity to major acid intermediates plants and a deep local talent pool. Jiangsu Acetic Acid Chemical has invested in modernizing its production units with improved energy integration, lowering manufacturing costs by up to 10% compared to older peers. Their strategy hinges on competitive pricing and growing partnerships with domestic resin producers, gradually capturing share from established multinational suppliers. Although their products occasionally exhibit higher impurity levels than Western equivalents, ongoing process improvements have narrowed the quality gap. The company’s export focus has grown, supplying Asian neighbors and selectively targeting emerging markets in Africa and South America. Backed by strong state support for the chemical industry in China, Jiangsu Acetic Acid Chemical is poised for further capacity additions and is rapidly gaining traction as a cost‑effective alternative in the global TMA market.

Sinopec Shanghai Petrochemical Company

Sinopec Shanghai Petrochemical Company, a subsidiary of China Petroleum & Chemical Corporation, leverages one of the nation’s largest refining‑chem complex to supply trimellitic anhydride alongside a slate of co‑products. The scale and integration of Sinopec’s Shanghai facility allow it to process by‑product streams efficiently and maintain competitive pricing. While historically focused on domestic markets, Sinopec has ramped up exports to Southeast Asia and the Middle East, positioning itself as a reliable backup to Western producers during tight supply periods. Sinopec has invested in digital plant management systems that enhance throughput and reduce downtime, addressing past quality inconsistencies. The company’s deep pockets, under the Sinopec umbrella, support aggressive capital expenditures and feedstock acquisitions, ensuring secure raw material supplies. Through partnerships with local resin formulators, Sinopec is also developing value‑added TMA blends for specific applications, gradually moving up the value chain. Although it still trails technology leaders in product sophistication, Sinopec’s cost leadership and scale make it a formidable competitor, especially in price‑sensitive regions.

CABB Group GmbH

CABB Group, headquartered in Germany, specializes in high‑purity anhydrides—including trimellitic anhydride—targeting niche applications in electronics, pharmaceuticals, and specialty polymers. Its finely tuned batch processes and proprietary purification steps yield TMA with extreme purity levels, meeting the exacting requirements of semiconductor encapsulants and medical‑grade resins. Although CABB’s overall capacity is relatively small, the company commands premium pricing and enjoys strong loyalty from customers whose end uses cannot tolerate trace impurities. CABB’s strategic emphasis on quality and service over volume shields it from price competition, allowing it to maintain healthy margins. The company’s global sales network, while lean, includes technical application specialists colocated with key customers in the United States, Europe, and Asia, facilitating rapid problem resolution and new product co‑development. CABB continually reinvests in its German and U.S. facilities to incorporate the latest filtration and distillation technologies, underpinning its reputation for reliability. As a highly focused specialist, CABB holds a top‑three position in ultra‑high‑purity TMA segments, serving as the partner of choice for premium manufacturers worldwide.

Solvay S.A.

Solvay S.A. has a long history in aromatic chemistries, and its TMA business benefits from decades of process optimization and integrated R&D. Operating key production sites in Europe, Solvay integrates its TMA output with specialty polymer initiatives—particularly in high‑performance polyesters and additives—allowing cross‑functional synergies that streamline innovation. Solvay’s continuous improvement programs have reduced production costs and improved environmental performance, aligning with the company’s robust sustainability framework. The firm’s global innovation hubs collaborate closely with customers to develop custom TMA‑based solutions, fostering deep technical relationships and ensuring recurring demand. Financially, Solvay maintains a balanced portfolio approach, using cash flows from its broader materials business to fund targeted TMA asset upgrades rather than large greenfield projects. Solvay’s presence in emerging markets has grown through joint ventures and licensing agreements, positioning it to capture incremental demand in Asia and Latin America. Overall, Solvay ranks among the top five global TMA producers, distinguished by its blend of specialty focus, technical service excellence, and sustainable manufacturing leadership.

The report provides a detailed analysis of the Trimellitic Anhydride (TMA) market across various regions, highlighting the unique market dynamics and growth opportunities in each region.

- US

- Canada

- Mexico

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Brazil

- Argentina

- Rest of Latin America

>>> Need A Different Region Or Segment? Download PDF Sample

Key Takeaways

- The global Trimellitic Anhydride (TMA) market is expected to grow significantly from 2024 to 2032, driven by technological advancements, increasing demand, and government investments in urbanization.

- The market is characterized by a diverse range of manufacturers, product types, and applications, catering to different consumer needs and preferences.

- Regional insights highlight the unique market dynamics and growth opportunities in various regions, including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- The competitive landscape features key players who have created a dynamic and diverse market environment through collaborations, mergers and acquisitions, and innovative product developments.

- Market trends such as technological advancements, sustainability, customization, and digital transformation are shaping the growth and development of the Trimellitic Anhydride (TMA) market.

- Despite the positive outlook, the market faces challenges such as regulatory compliance, high initial investment costs, and economic uncertainties.

- The report provides comprehensive coverage of market size, market share, growth factors, and strategic insights to help businesses navigate the dynamic Trimellitic Anhydride (TMA) market and achieve long-term success.

By leveraging the information provided in this report, businesses can develop effective strategies, address market challenges, and capitalize on growth opportunities to ensure sustainable growth and long-term success in the global Trimellitic Anhydride (TMA) market.

- Introduction

- Objectives of the Study

- Market Definition

- Research Scope

- Currency

- Key Target Audience

- Research Methodology and Assumptions

- Executive Summary

- Premium Insights

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top Investment Pockets

- Industry Trends

- Market Dynamics

- Market Evaluation

- Drivers

- Restraints

- Opportunities

- Challenges

- Global Trimellitic Anhydride (TMA) Market Analysis and Projection, By Companies

- Segment Overview

- FHR

- Polynt

- MGC

- Jiangsu Zhengdan

- Wuxi Baichuan

- Anhui Taida

- Global Trimellitic Anhydride (TMA) Market Analysis and Projection, By Type

- Segment Overview

- MC Method Product

- MGC Method Product

- Global Trimellitic Anhydride (TMA) Market Analysis and Projection, By Application

- Segment Overview

- Trimellitate Plasticizer

- Powder Coatings

- Insulation Materials

- Polyester Resin

- Others

- Global Trimellitic Anhydride (TMA) Market Analysis and Projection, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- Middle East

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Global Trimellitic Anhydride (TMA) Market-Competitive Landscape

- Overview

- Market Share of Key Players in the Trimellitic Anhydride (TMA) Market

- Global Company Market Share

- North America Company Market Share

- Europe Company Market Share

- APAC Company Market Share

- Competitive Situations and Trends

- Coverage Launches and Developments

- Partnerships, Collaborations, and Agreements

- Mergers & Acquisitions

- Expansions

- Company Profiles

- FHR

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Polynt

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- MGC

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Jiangsu Zhengdan

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Wuxi Baichuan

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Anhui Taida

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

List of Table

- Drivers of Global Trimellitic Anhydride (TMA) Market: Impact Analysis

- Restraints of Global Trimellitic Anhydride (TMA) Market: Impact Analysis

- Global Trimellitic Anhydride (TMA) Market, By Technology, 2023-2032(USD Billion)

- global MC Method Product, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global MGC Method Product, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global Trimellitate Plasticizer, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global Powder Coatings, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global Insulation Materials, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global Polyester Resin, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global Others, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

List of Figures

- Global Trimellitic Anhydride (TMA) Market Segmentation

- Trimellitic Anhydride (TMA) Market: Research Methodology

- Market Size Estimation Methodology: Bottom-Up Approach

- Market Size Estimation Methodology: Top-down Approach

- Data Triangulation

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top investment pocket in the Trimellitic Anhydride (TMA) Market

- Top Winning Strategies, 2023-2032

- Top Winning Strategies, By Development, 2023-2032(%)

- Top Winning Strategies, By Company, 2023-2032

- Moderate Bargaining power of Buyers

- Moderate Bargaining power of Suppliers

- Moderate Bargaining power of New Entrants

- Low threat of Substitution

- High Competitive Rivalry

- Restraint and Drivers: Trimellitic Anhydride (TMA) Market

- Trimellitic Anhydride (TMA) Market Segmentation, By Technology

- Trimellitic Anhydride (TMA) Market For Live Attenuated, By Region, 2023-2033 ($ Billion)

- Global Trimellitic Anhydride (TMA) Market, By Technology, 2023-2032(USD Billion)

- global MC Method Product, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global MGC Method Product, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global Trimellitate Plasticizer, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global Powder Coatings, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global Insulation Materials, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global Polyester Resin, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- global Others, Trimellitic Anhydride (TMA) Market, By Region, 2023-2032(USD Billion)

- FHR: Net Sales, 2023-2033 ($ Billion)

- FHR: Revenue Share, By Segment, 2023 (%)

- FHR: Revenue Share, By Region, 2023 (%)

- Polynt: Net Sales, 2023-2033 ($ Billion)

- Polynt: Revenue Share, By Segment, 2023 (%)

- Polynt: Revenue Share, By Region, 2023 (%)

- MGC: Net Sales, 2023-2033 ($ Billion)

- MGC: Revenue Share, By Segment, 2023 (%)

- MGC: Revenue Share, By Region, 2023 (%)

- Jiangsu Zhengdan: Net Sales, 2023-2033 ($ Billion)

- Jiangsu Zhengdan: Revenue Share, By Segment, 2023 (%)

- Jiangsu Zhengdan: Revenue Share, By Region, 2023 (%)

- Wuxi Baichuan: Net Sales, 2023-2033 ($ Billion)

- Wuxi Baichuan: Revenue Share, By Segment, 2023 (%)

- Wuxi Baichuan: Revenue Share, By Region, 2023 (%)

- Anhui Taida: Net Sales, 2023-2033 ($ Billion)

- Anhui Taida: Revenue Share, By Segment, 2023 (%)

- Anhui Taida: Revenue Share, By Region, 2023 (%)

Infinitive Data Research provides comprehensive market research, offering in-depth market analysis to help companies understand their target market and industry competition. This research predicts the market acceptance of your brand and products, ensuring informed decision-making for business success.

Competitor Analysis in the Trimellitic Anhydride (TMA) Industry

Conducting a competitor analysis involves identifying competitors within the Trimellitic Anhydride (TMA) industry and studying their various marketing strategies. This comparative data allows you to assess your company's strengths and weaknesses relative to competitors, providing insights to enhance your market position.

Importance of Continuous Market Research

Consistently conducting market research is essential for minimizing risk at every stage of business operations. Trimellitic Anhydride (TMA) market research enables you to collect qualitative and quantitative data, which, when properly analyzed, leads to wise decisions that align with user and customer needs. Below are some crucial lessons learned through the Trimellitic Anhydride (TMA) market research process:

Key Dimensions of Trimellitic Anhydride (TMA) Market Analysis

- Trend and Pattern Identification: Analyzing data to spot market trends and patterns.

- Pricing Analysis: Assessing keyword pricing strategies.

- Actionable Insights: Implementing insights derived from data analysis.

- Market Potential: Evaluating the potential of the Trimellitic Anhydride (TMA) market.

- Competitor Analysis: Studying competitors' strategies and performance.

- Location Analysis: Assessing optimal locations for market penetration.

- Distribution Channels Analysis: Evaluating the effectiveness of distribution channels.

- Market Size and Growth Rate: Measuring market size and growth potential.

- Market Profitability: Assessing profitability prospects.

- Key Success Factors: Identifying critical factors for success.

- Cost Structure: Understanding the cost structure within the Trimellitic Anhydride (TMA) industry.

Target Audience for the Report

This report is valuable for a diverse audience, including:

- Trimellitic Anhydride (TMA) Market Manufacturers: To understand market dynamics and enhance production strategies.

- Investors and Financing Companies: To assess investment opportunities and risks.

- Trimellitic Anhydride (TMA) Market Suppliers: To identify market demands and supply chain efficiencies.

Necessity of the Report

Making Crucial Business Decisions

Understanding the Trimellitic Anhydride (TMA) market, competition, and industry landscape is vital for making informed business decisions. Without current and relevant market research, decisions may be based on outdated or irrelevant information, potentially harming the business.

Securing Investment Funds

Attracting investors requires demonstrating thorough market research. Investors need assurance that you understand the sector, current and potential competition, and whether your idea addresses a market need.

Identifying New Business Opportunities

Trimellitic Anhydride (TMA) market research goes beyond understanding trends and consumer behavior. It identifies new revenue streams and opportunities for business pivots. These insights can lead to strategic changes in the business model, promoting growth and adapting to market challenges.

Avoiding Business Failures

Market research also plays a crucial role in risk mitigation. It can reveal when not to pursue certain actions, saving the company from potential losses in revenue, brand image, and more. This proactive approach is often overlooked but is essential for long-term success.

Conclusion

Infinitive Data Research's comprehensive Trimellitic Anhydride (TMA) market research provides critical insights for making solid business decisions, securing investments, identifying new opportunities, and avoiding potential failures. Understanding market dynamics through continuous research ensures your company remains competitive and thrives in the Trimellitic Anhydride (TMA) industry.